Seven vital Industry 4.0 automotive technologies

Last updated on November 28th, 2022

We are in the midst of a manufacturing revolution known as Industry 4.0. This fourth industrial revolution, the latest in the history of such revolutions dating back almost 300 years, also inspired the rise of Industry 4.0 automotive technologies which include cutting-edge breakthroughs like additive manufacturing, virtual and augmented reality, the Internet of Things and, of course, artificial intelligence. Any one of these technologies has the potential to change how we manufacture goods. When taken together, they can change everything.

The previous three industrial revolutions were fundamental to changing the way we work, the tools we use, and the products of our labour. The first industrial revolution (1760-1840) was propelled by mechanization and steam power, the second (1870-1914) was powered by mass production and electricity, and the third (1950-2000) was driven by automation and computerization.

While the global Industry 4.0 market was worth US$65 billion in 2021, that value is expected to grow by an impressive CAGR of 20.6% to US$166 billion by 2026. With such momentous implications for Industry 4.0 automotive technologies (not to mention all the marketing hype), it can be easy to miss the practical values that they hold.

Benefits and challenges of shifting to Industry 4.0

The main objective of implementing Industry 4.0 automotive technologies is to design a more efficient, cost-effective, and precise manufacturing process.

Why are companies resistant to embracing Industry 4.0 technologies?

The transition to Industry 4.0 is a challenge for most OEMs and suppliers. Before they can start adopting Industry 4.0 automotive technologies, they need the appropriate tools and talent to implement the processes and systems. They also need the expertise to deal with the many logistical problems they will face, including:

- Eliminating threats to their manufacturing data systems’ cybersecurity

- Dealing with the complexities and costs of introducing new technologies

- Dispelling the fear that robots will replace humans in the workforce

In the end the benefits outweigh the challenges, as illustrated below.

What are the benefits of moving to Industry 4.0 technologies?

Industry 4.0 automotive technologies, processes, and systems enable manufacturers to create smart factories that are more productive, efficient, and responsive. Using cloud technology, big data analytics, and manufacturing analysis tools, OEMs and suppliers can benefit from manufacturing intelligence that can deliver actionable insights from their data, including solutions to:

- Better use their resources and materials

- Improve throughput and decrease downtime

- Reduce product failure and rework rates

- Lower overall maintenance and operating costs

- Inspire innovative ideas and opportunities

Industry 4.0 automotive technologies have a positive impact on quality management and production throughput, which can lead to improved productivity and profitability.

Why is automotive the best industry to see this shift?

The automotive industry is a technology-driven and precise engineering environment, where data analytics in manufacturing is one of the primary drivers of throughput efficiency. Industry 4.0 is at the forefront of helping OEMs and suppliers in the automotive industry on their digital transformation journey, by enabling them to:

- Interact with their customers more directly

- Deliver products and services more efficiently

- Rethink the way they are operating their plants

OEMs and suppliers in the automotive industry are increasingly leveraging the real benefits of Industry 4.0 automotive technologies through continued adoption.

7 key Industry 4.0 automotive technologies

Let’s take a closer look at seven of the most important Industry 4.0 technologies that are most relevant to the automotive industry.

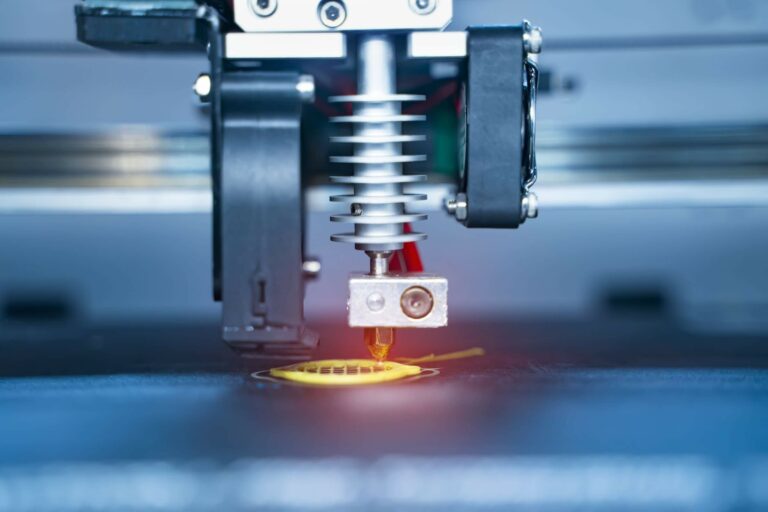

1. Additive Manufacturing

Additive manufacturing is a rapidly growing technology. It enables designers and engineers to create prototypes of products and components in a fraction of the time, compared to using traditional methods. The ability to quickly and accurately manufacture, test, and customize automotive parts and components is inspiring. These automotive innovations are enabling engineers to create parts that would otherwise be impossible to produce with traditional manufacturing processes. Additive manufacturing can include:

3D printing: Most automakers use 3D printing to produce a prototype of a part before they introduce it into their mainstream production line. After deployment of a vehicle, this practice can proactively reduce disruptions in the supply chain, by replacing faulty parts without costly wait times often experienced with outside suppliers. A recent survey on the benefits of 3D printing revealed that 69% of respondents use it for its exceptional capability to produce complex parts. Air intakes, exhaust system parts, and ducting are some of the most popular components to be printed, but smaller custom parts, like brackets, spacers, and grommets are becoming more common.

Designated centers: Additive manufacturing is giving automakers, suppliers, and Tier 1s the tools to enhance their individual creativity, fuelling their quest to out-innovate one another. Major OEMs, like BMW and Volkswagen, are printing thousands of parts per year in their designated additive manufacturing centers. This has created advantages with unlimited possibilities for them, and for their competitors to discover.

Microfactories: Additive manufacturing can lead to a new type of factory altogether, namely the microfactory. An American automobile manufacturing company, Local Motors, pioneered the additive manufacturing revolution in the automotive industry. They operated several microfactories, dedicated to producing vehicles locally, using additive manufacturing techniques.

Like most Industry 4.0 automotive technologies, additive manufacturing can improve processes throughout the full product lifecycle.

2. Virtual and Augmented Reality

Virtual reality (VR) and augmented reality (AR) are often confused when it comes to modern manufacturing processes.

Virtual reality: When thinking about virtual reality, most people’s thoughts gravitate to gaming. Shooting ducks in Duck Hunt or dodging bullets in Superhot are entertaining, but they don’t capture the full potential of this revolutionary technology, virtual reality. Take Mercedes-Benz for example, they have implemented a virtual assembly station. It is similar to a video game console, with motion control functions that allow designers to perform the virtual assembly of parts and test out different situations that can arise, using an avatar of their choosing.

Virtual reality can also be used to prevent the delayed detection of design errors in a prototype – a major predicament in developing a new vehicle model. The ability to simulate prototypes in terms of their volume and size, and get a detailed view of how all the parts are connected together, is transforming the way engineers develop and build new designs.

Audi is one of the major OEMs that has embraced this technology, with their VR holodeck, which is a virtual environment that houses a 3D image of a car. The holodeck gives engineers the ability to visualize a realistic concept of a new vehicle model in the early stages of conception. This saves time and cuts costs, by reducing the physical testing efforts during the development stages of the product.

Imagine test driving a car without driving it off the lot. The VR experience takes place in a simulated, isolated reality environment. For car retailers this means they can reduce showroom size, which in turn helps them significantly cut rent costs, inventory, and salaries, while enhancing the customers’ experience. Plus, customers have the ability to change a vehicle’s configuration and aesthetics in a matter of seconds – before they order their dream car. This flexibility is just one of the reasons why Audi has deployed more than 1,000 VR showrooms and are planning on expanding this concept around the world.

Augmented reality: This technology merges digital creations with the physical world. Users are able to see existing environments overlaid by computer-generated images. AR technology enables advanced driver assistance systems that help drivers stay more focused on the road.

For example, today’s drivers rely predominantly on cell phones for GPS in their car, and it is hard not to get distracted when a message pops up on the screen. With augmented reality, a head-up display projects data, such as warning signals, driving speed, navigation information, and much more, directly onto the windshield. The display is perceived by drivers as part of their view of the road, eliminating the need for them to look down at their phones or instrument panels. Hyundai and WayRay have released the world’s first Holographic Augmented Reality Navigation System, and it looks like it is straight out of a sci-fi movie.

3. Internet of Things (IoT)

From cell phones, televisions, and lamps to airplane engines and oil rig drills – the Internet of Things (IoT) can connect it all. If it has an on/off switch, chances are IoT technologies can be used to connect it to the internet and other connected devices, to facilitate the sharing of data.

The Internet of Things is notably transformative for the automotive industry, which can be attributed to the concept of connected vehicles and smart factories. On a modern production line, Industrial IoT (IIoT) technologies employ a network of sensors, scales, and gauges. They are used to collect data and, leveraging cloud-based manufacturing optimization software, transform it into valuable and actionable insights about productivity and safety. The data can also help reduce scrapping and reworking of parts, by leveraging predictive quality control analytics to identify problems that could lead to faulty parts before they happen.

In the factory: Using IIoT technologies can help optimize product development and delivery times in various areas within manufacturing plants. A study has shown that manufacturers in the automotive industry that implement IIoT smart factory initiatives could see productivity gains of up to 4.4% over the next year.

Machines that are equipped with sensors that can measure and reduce excess energy consumption can be instrumental in helping lower production costs and fuel environmentally sustainable operations. Production output can also benefit from IIoT technologies, with improved asset tracking that alerts manufacturers when stock is low, and enables them to automate their inventory management systems. Additionally, the technology can be used to identify potential equipment failures and decrease unexpected downtime.

On the roads: With IoT-connected vehicles, safety on the roads will be greatly improved, by identifying accidents and poor driving skills in real time. The IoT-enabled cars will be able to automatically detect collisions and immediately contact emergency services. The same technology can also be used to monitor driving habits and send recommendations to drivers, empowering them to continuously improve their driving skills.

Urban traffic congestion is a problem in every major city. IoT technologies can help control traffic to make morning commutes hassle free. While preventing accidents will result in less congestion on the roads, IoT devices and smart technologies can also be used for swarm intelligence in traffic control, allowing traffic operators to coordinate car movements, to reduce common chokepoints when roads are busiest during the day.

Along with improving driving conditions on the roads, IoT technologies can also be used to improve the roads themselves. Road construction companies can use IoT technologies to detect maintenance needs, to ensure roads are not left in poor condition for extended periods of time.

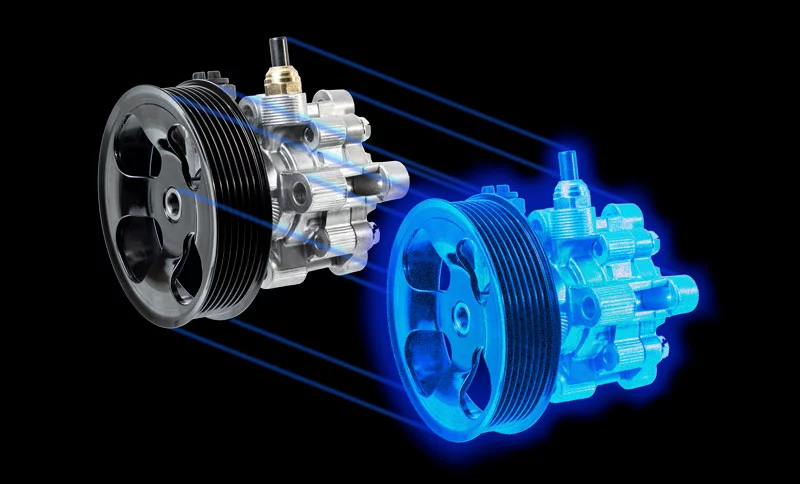

4. Digital twins

In modern manufacturing, a digital twin is a virtual replica of a product or a section of a production line. Industry 4.0 automotive technologies are employed to create digital twins. They use machine learning and AI manufacturing solutions, combined with IoT sensors and advanced automotive analytics programs to create the models. The two main categories of digital twins are low fidelity and high fidelity. Each of these has different characteristics.

Low-fidelity digital twins: These provide a holistic view of the whole production process and the physical parts being produced, to deliver real-time operational status and product data updates.

Manufacturers can use these digital twins to analyze production lines and components, reduce scrap and rework rates, accelerate root cause analysis, and improve product throughput and quality.

High-fidelity digital twins: These are virtual models based on the fixed physical specifications of a particular object or system. Since high-fidelity digital twins do not display the operational status of a part or process, automotive manufacturers tend to use low-fidelity digital twins, which illustrate how a component or system is performing.

5. Autonomous robots

Robots enabled with machine learning and artificial intelligence (ML/AI) capabilities can perform dangerous and complicated tasks that are too difficult or unsafe for humans. They can handle heavy loads, toxic materials, and repetitive tasks, thus helping manufacturers reduce accident rates and improve efficiency.

The outbreak of the coronavirus pandemic led to an unprecedented increase in demand for autonomous robots in the automotive industry, and that demand continues to grow. In fact, the demand is so great that the global automotive robotics market value is projected to increase by a CAGR of 12.8% to $16.29 billion by 2028.

In the manufacture of vehicles there are a multitude of parts and components, and they require numerous manufacturing processes to produce them. Below are some of the best-suited applications for autonomous ML/AI enabled robots:

Welding: Robots with high payload capabilities and flexible reach can spot weld car body panels, while smaller robots can weld subassemblies, like specialized brackets and mounts.

Assembly: Dexterous robotic arms can assemble complex parts, such as motors, at high speed. They can also perform precise bolt driving, wheel fitting, and windshield installation tasks.

Machine tending: Robots can easily pick up hot mouldings from a die casting machine or help with the loading and unloading of CNC machine centers.

Material removal: A robot can follow a complex track repeatedly, making it the perfect precision tool for accurate cutting and trimming jobs.

Painting: Robots are agile and precise, ideal for painting complex, multi-faceted components – and they are immune to toxic spray fumes.

Logistics: Robots and other automated vehicles, like forklifts, can be employed on a factory floor to move materials and parts from storage areas to where they are needed.

Robots are complementary to the people on the production line. Workforces should be reassured that they are still needed to perform tasks that require personal input, like applying finishing touches to a product or conducting final quality controls.

6. Big data analytics

Big data, the vast amount of information that inundates manufacturing data collection software daily, can be a very valuable resource, if manufacturers have the ability to analyze and act on the insights gathered from it. In 2021, the big data market in the automotive industry was worth over US$4.2 billion. Growing by a CAGR of over 16%, big data’s value is expected to exceed US$9.9 billion by 2027. That is a lot of valuable information.

Big data analytics enables manufacturers in the automotive industry to combine the vast amounts of information from their enterprise resource planning (ERP) systems and the data collected from their different departments and suppliers. Using manufacturing analytics software, they can analyze the data to identify opportunities that can help them improve throughput efficiency and quality. The insights can also be used to streamline their procurement processes, by analyzing the data for demand prediction.

7. Artificial Intelligence

The automotive industry has a history of harnessing the newest technologies to bring safe, efficient and innovative vehicles to market. It is no surprise that, as a result of this journey toward better and safer vehicles, AI has been playing a huge role in the industry and will continue to do so.

On the floor: AI-driven production optimizations starts on the factory floor. Traditionally, machines on a production line were encoded with a set of pre-programmed instructions to perform the same task over and over again. AI solutions for manufacturing have enabled engineers to analyze data from machines in real time, empowering them to continuously adapt and adjust the instructions to the machines, making them perform at maximum efficiency levels.

In the vehicle: Using AI-enabled predictive maintenance and quality control analytics on vehicle data can alert manufacturers to potential failure points on the production line. The insights can also be used to identify defects in parts of the vehicle in real time so adjustments can be made quickly, thereby reducing production costs and improving product quality and throughput.

On the road: AI in automotive manufacturing can deliver insights used to make predictions and respond to changing situations in manufacturing processes, but its capabilities go beyond the factory floor. The potential for AI applications extends to maintenance and even the driving experience itself. By implementing AI and Industry 4.0 technologies, manufacturers can greatly minimize driver error. For example, driver monitoring allows for vehicles to determine when someone is falling asleep at the wheel and assist drivers to stay awake. In case of an accident, AI can also adjust airbags to account for the driver’s specific body orientation, to provide a cushiony landing.

The most talked about AI innovation on the road, however, is in autonomous vehicles. AI and Industry 4.0 are fuelling a new world of transportation, where drivers are not required and cars are able to drive themselves. Artificial intelligence is expected to help reduce accidents and alleviate traffic congestion, and it is estimated that 1 in 10 vehicles in the world will be self-driving by 2030.

In a real-world use case: A major Tier 1 supplier wanted to leverage machine learning and artificial intelligence techniques on production assembly data, to reduce the rate of product fallout and associated rework for axle assemblies. Just one of the supplier’s production lines involved over 20 different operations that generated more than 200 measurements per assembled unit. Considering the large volume of data, it was difficult to pinpoint the sources of failures. Using machine learning and artificial intelligence, Acerta’s team identified several key measurements from the manufacturing process that predicted backlash failures. This enabled the client to narrow down the list of likely causes of the failures, without having to manually go through the big data.

By using Acerta’s LinePulse, with its anomaly detection and capability metrics modules, there was a 65% reduction in failure and rework rates, a significant improvement in first time yield, and considerable cost reductions. The customer implemented LinePulse in all of their facilities globally and prioritized further investments into Industry 4.0 technologies.

Now that we have given you a peek into the key Industry 4.0 automotive technologies that are driving this modern-day industrial revolution, don’t you want to learn how to optimize manufacturing processes in your factory?

Acerta’s LinePulse solution helps you build better parts more efficiently by engaging Industry 4.0 automotive technologies that use machine learning and artificial intelligence on your product and production data. LinePulse aggregates and analyzes all relevant data from all of your sources to proactively deliver intelligence that uncovers defects, provides root cause analysis, and improves first time yield. Want to learn more? Get in touch.

Share on social: